In order to meet the needs of more users, our factory will newly configure multiple CNC lathes on the basis of automatic lathes in 2016.

Because of the high commissioning time and commissioning costs for a single automatic lathe turning, the number of orders is also limited.

The configuration of CNC machine tools has solved the requirements of many types of users, complex shapes and high precision, which has effectively improved the machining capacity of our factory.

The following are some representative products processed by our company for users.

The maximum machining outer diameter of the main shaft can reach 80MM under continuous feeding conditions. When the chuck is separately processed, the maximum rotary diameter is 360 MM; however, the minimum size of machining is not limited. The material of the product mainly consists of copper, iron, aluminum and stainless steel. Other materials can also be processed. The material is processed according to the drawings provided by the customer.

Because of the high commissioning time and commissioning costs for a single automatic lathe turning, the number of orders is also limited.

The configuration of CNC machine tools has solved the requirements of many types of users, complex shapes and high precision, which has effectively improved the machining capacity of our factory.

The following are some representative products processed by our company for users.

The maximum machining outer diameter of the main shaft can reach 80MM under continuous feeding conditions. When the chuck is separately processed, the maximum rotary diameter is 360 MM; however, the minimum size of machining is not limited. The material of the product mainly consists of copper, iron, aluminum and stainless steel. Other materials can also be processed. The material is processed according to the drawings provided by the customer.

Specifications longer computer lathe processing Specifications longer computer lathe processingThis is a long NC machining part, because the product is too large, only a partial close-up shot. Left specifications 25MM*300MM Two-end processing, intermediate polishing Left image Product material: Aluminum Machinable materials: aluminum, iron, stainless steel, copper, etc. |

A stainless steel pin processed by our company, with the big picture attached. A stainless steel pin processed by our company, with the big picture attached.(Knurled section) melted into plastic parts, Exposed tip, small flat position for positioning. Processing features: tip, deep hole |

Large CNC Lathe Turning Example Large CNC Lathe Turning ExampleThe left part of the drawing is a larger-sized stainless steel-turned part. The material is SUS304, hexagonal-to-edge H45mm, threading, turning inner wall, and two-step through hole. Although the shape is simple, the amount of turning is large. |

Slender shaft CNC lathe turning machining parts Slender shaft CNC lathe turning machining partsAs the product is longer, the left picture is only a partial picture of the product. Material: Aluminum Size: The largest outer circle 12MM, total length 150MM Processing features: slender shaft machining |

An example of a small aluminum turning part. An example of a small aluminum turning part.Outer diameter 12mm length 15mm, two flat hole, side hole screw M3. Processing features: punching and tapping thread on the side of the power cutter head. |

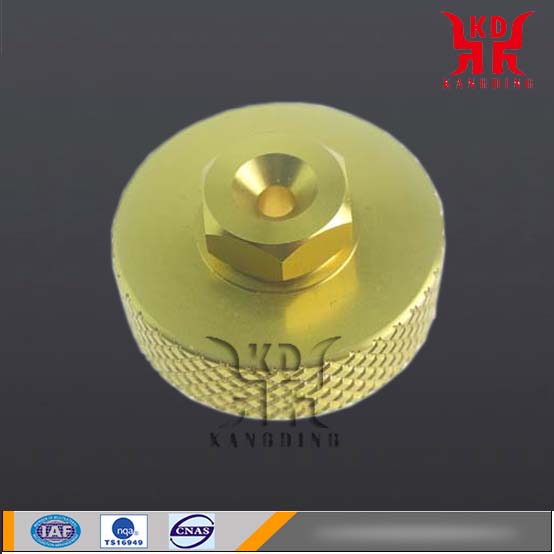

The left is a larger size internal and external threads machined by a CNC lathe, and the plastic is screwed into the copper insert. The left is a larger size internal and external threads machined by a CNC lathe, and the plastic is screwed into the copper insert.Its external thread is generally non-standard to increase pitch and flat tooth angle, suitable for computer numerical control lathe processing. According to the user's drawings, you can walk out of any tooth pitch or double teeth. The cutting head of the power cutter head does not affect the accuracy of the thread. Machinable range: M3-20 (with internal thread) The product on the left is a common part of our company, view slotted self-tapping copper inserts Processing features: internal and external teeth |

Simple aluminum CNC turning parts Simple aluminum CNC turning partsSpecifications on the left: Outside diameter 28MM* Length 25MM Material:6063-T6 The CNC lathe has a tool holder that can automatically change the tool. After the machining parts are clamped once, the CNC system can control the lathe to automatically select and change the tool according to different procedures. Automatically change the spindle speed of the machine tool, the amount of feed, the movement path of the tool relative to the workpiece, and other auxiliary functions. Continuously and automatically feed the respective machining surface of the workpiece. |

Using a side milling NC lathe parts Using a side milling NC lathe partsProcessing features: side milling, axial groove. Both parts are convex side milling a longitudinal axial plane four cylinder, the curved groove side milling axial plane. CNC lathes with power cutter heads, tiny milling inserts mill large flats or grooves of various sizes. Both of the products on the left are made of brass. The nickel-plated part is the connector of the data network cable. The connection plug of a computer or video equipment is common. The outer diameter is 16mm and the length is 25mm. Another copper piece is the copper spool of the flow control valve, with a maximum diameter of 11mm and a total length of 30mm. |

Two large size stainless steel turned parts Two large size stainless steel turned partsEnlarged view Material:SUS304 The largest outer size (on the right): 1.25inch Product Features: Internal and external circles are transitional arcs |